Airport Industrial Park

685 Aviation BLVD.

Georgetown, SC 29440

Phone: 843.546.1044

Toll Free: 800.541.1044

Email: SALES@CON-SERVINC.COM

PF

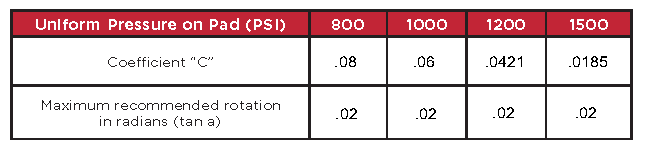

Thickness Required = ((W/2) x tan a) / "C"

CON-SERV Inc recommends an 11 ga. plate be laminated every 2" in pads over 2" thick for strength and stability.

Physical Properties:

Type |

N/A PF |

Element |

N/A Alternate Lower |

Max. Design Pressure (psi) |

N/A 1500 |

Durometer (Shore A) |

N/A 90 |

Tolerance of Durometer |

N/A ± 5 |

Max. Compressive Strength (psi) |

N/A 18000 |

Lip |

N/A 50L |

Thickness Variables |

N/A

PSI PF CHART |

|

N/A

The CON-SLIDE bearing guide specification for Type CSB Can be utilized as a guide for PTFE, preformed fabric pad-backed bearings. The preformed fabric pad shall comply with the AASHTO specification DIV. II SECT. 18. The preformed fabric pads shall be composed of multiple layers of 8 oz. cotton duck impregnated and bound with high-quality natural rubber or of equivalent and equally suitable materials compressed into resilient pads of uniform thickness. The number of plies shall be such as to produce the specified thickness, after compression and vulcanizing. The finished pads shall withstand compression loads perpendicular to the plane of the laminations of not less than 10000 pounds per square inch without detrimental reduction in thickness or extrusion. The pad also shall comply with MI-C-882-E Military Specification and P.C.I. Prestressed Concrete Design Manual. |