This blend (CSB) was formulated for use against a smooth stainless steel surface.

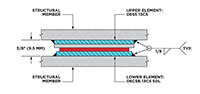

The CSB system consists of an upper and lower element. The PTFE surface (1 only) is on the lower element. It is nominally 1/16" thick and is control-bonded to a 10-gauge carbon steel (CS) back-up sheet. The upper element is composed of a 20-gauge stainless steel (SS) sheet (RMS<20) resistance welded to a 10-gauge carbon steel (CS) back-up sheet.

The blended CSB material used for this bearing is composed of virgin (unreprocessed) PTFE resin tested per ASTM D4894 or ASTM D4895 and reinforcing agents including milled glass fibers. This structural material has the following representative mechanical and physical properties:

- Tensile Strength: 3300 psi

- Elongation: 300%

- Specific Gravity: 2.14 - 2.21

Actual values per lot are available upon request which might vary due to processing factors.

The design engineer shall determine the square inches of bearing area required for the lower element by dividing the load by the allowable pressure from the graph. The upper element is sized for the movement after the lower element is sized for load.

CON-SERV Inc can supply any practical size cut from stock steel. Size is out to out of back-up plate.

For ease of installation, CON-SERV recommends a back-up plate 1" larger than the CSA or CSB size to allow a 1/2" recess all around. This recess must be provided for plates requiring a seal weld.

Certifications on the epoxy, steel and CSB material are available upon request.